As one of the top-selling promo product categories, it would seem that most people already know that incorporating apparel into your promotions is an effective way to get your message across. From trendy new products to high-tech gadgets to tried-and-true merchandise like caps and t-shirts, no doubt there is an apparel item that meets your needs and budget. And while selecting the item may seem like a no-brainer, it’s also worthwhile to understand that there are several options for decorating apparel that can greatly impact the effectiveness of your promotion. Ultimately, the goal is to showcase your brand, highlight your message, and ensure that the decoration on the item lasts as long as the item itself. Working with a sales rep who understands the nuances of apparel decoration is one easy way to ensure that the decoration method fits the item, however, it’s beneficial for you as the buyer to at least understand a few basics and to know that one size (or in this case, one decoration method) does not fit all.

THE BASICS

Screen-printing

The vast majority of t-shirts are screen-printed (also known as silk screening). This is a method of printing graphics that uses thick inks that lay on top of the shirt rather than ones that soak into the garment. The most popular ink used in the garment printing industry is plastisol ink, because it is easy to print, will not dry in the screen, and it adheres to most fabrics. But in addition to traditional inks, soft-hand and water-based inks are perfect for vintage-look t-shirts or lightweight material. Screen-printed garments tend to last longer, however, due to the colors needed for the design, set-up costs may be higher than with other imprinting techniques and generally, there is a minimum number of items required to place an order.

Heat Transfer

In this method, the design is first printed on heat-sensitive material and then that material is applied to the garment using a heat press, which is great for finely detailed designs or small text. Heat transfer can also be used to recreate full-color designs on garments that cannot be screen-printed because of the type of material (nylon, silk, satin, etc). With heat transfers, the drawbacks are that each garment may cost a bit more, plus the design will eventually fade over time and may crack or shrink if put in a dryer.

Direct to Garment Printing

DTG printing is inkjet technology (similar to an inkjet printer). This technique uses water-based ink that is absorbed into the fibers of the material, which allows for greater detail than screen printing, giving the finished product a polished, professional look. This method preserves the softness of the garment and is great when only printing small quantities. Plus there’s no limit to the number of colors you can use. For larger quantities, however, DTG is slow when compared to screen-printing.

Embroidery

Embroidery is ideal for classic, corporate-style apparel, like woven shirts, jackets, hats, and sweaters. But just like screen printing, there are new options available. Techniques like puff embroidery and sequin embroidery can add a little something extra to your design. If the item needs to be decorated in an area that is difficult to reach (like the bill of a baseball cap) it’s often to embroider on a woven patch, then affix that to the fabric. Unfortunately, embroidery is not suited for small details or tiny text.

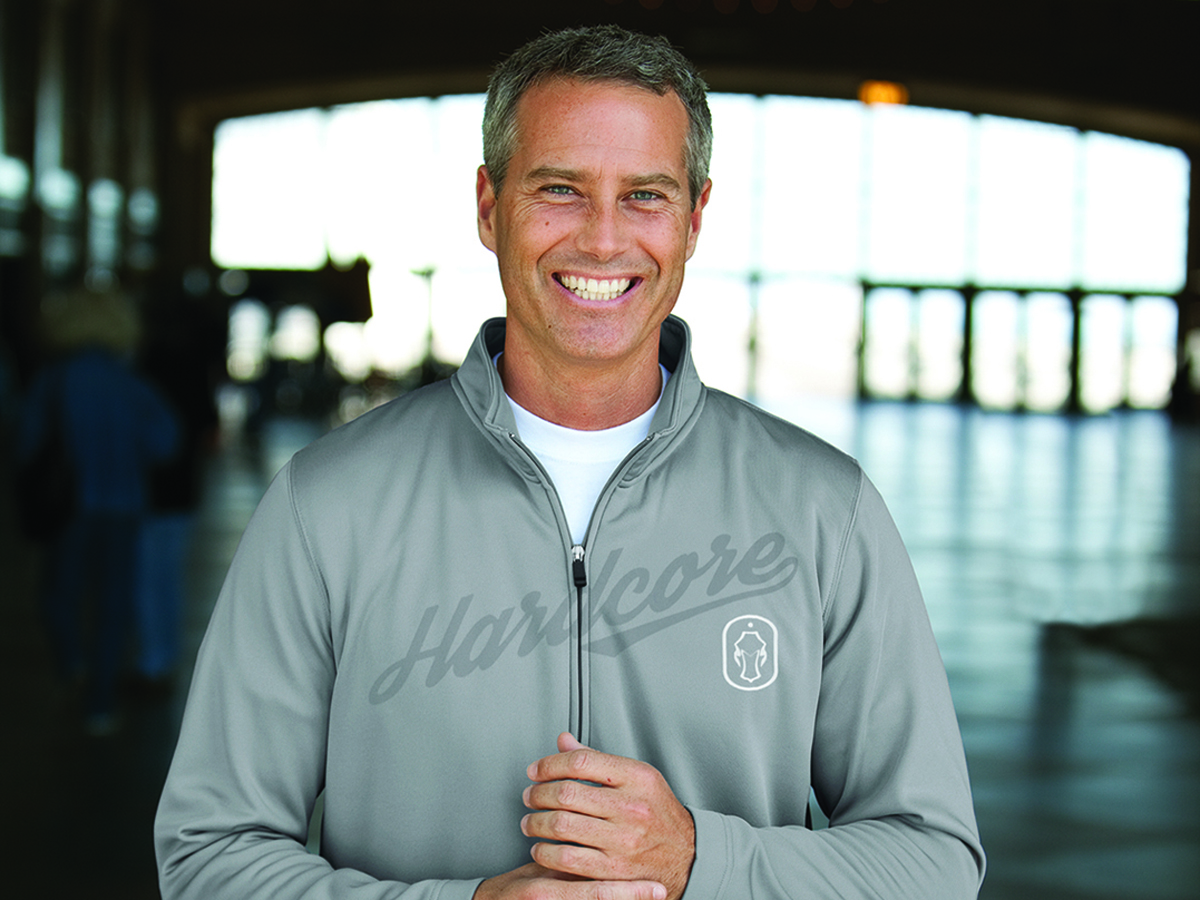

Debossing

This is where a custom metal-engraved die is heat pressed into the material, creating a tone-on-tone 3D effect that won’t fade or wash away. It’s a richer and more subtle than traditional decoration methods and works on practically any color garment. It’s best on thicker fabrics, like outerwear and performance or polar fleece, but can also be used on cotton, polyester, leather, and faux leather. And unlike embroidery, it won’t create holes in waterproof fabrics. Note that similar to debossing is the process of embossing. This is when the areas surrounding the logo or design is pressed into the garment. Here, the logo or design becomes a “negative” element of the design.

Laser Etching

Laser etching (or laser engraving) uses a laser to burn your design into the top layer of the fabric. The remaining image has a glossy, tone-on-tone look that is the same color but several shades darker than the original fabric color. It’s ideal for decorating unusual areas, like along seams or zippers, and is perfect for polar fleece and most polyester fabrics. Although it will be subtle on any color garment, it works best on medium colors and isn’t recommended for white or pastel colors.

New & Trendy

There are also many new, fun decoration techniques that you may or may not be familiar with. Many of these styles can be seen in retail products and are now crossing over into promotional apparel for a more custom look. Unique options like stain imaging, fabric appliques, rhinestones, custom zipper pulls and hoodie strings or contrasting color stitching might be available depending on the garment. And with items like caps or jackets and shirts, you can always consider customizing a hang tag or inside label in addition to regular decoration. For a really special look, you can even consider a combination of decoration techniques.

With so many creative options to choose from, it’s often best (and easier!) to rely on your Vernon account executive to help you find the right apparel for your next promotion.